服务热线< img border="0" src="http://wpa.qq.com/pa?p=2:2907815691:51" alt="免费在线咨询" title="免费在线咨询"/>

13636657709

服务热线< img border="0" src="http://wpa.qq.com/pa?p=2:2907815691:51" alt="免费在线咨询" title="免费在线咨询"/>

13636657709

|

Size |

10 | ||

|

Weight |

3/2 directional seat valve |

kg |

2.6 |

|

4/2 directional seat valve |

kg |

3.9 | |

|

Installation position |

any | ||

|

Ambient temperature range |

NBR seals |

°C |

-30 … +50 |

|

FKM seals |

°C |

-20 … +50 | |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oil |

HL, HLP |

FKM, NBR |

DIN 51524 |

|

|

Bio-degradable |

Insoluble in water |

HEES (synthetic esters) |

FKM |

VDMA 24568 |

|

HETG (rape seed oil) |

FKM, NBR |

|||

|

Soluble in water |

HEPG (polyglycols) |

FKM |

VDMA 24568 |

|

|

Other hydraulic fluids on request |

||||

electrical

|

Voltage type |

Direct voltage | AC voltage | ||

|

Available voltages |

V |

12 / 24 / 42 / 96 / 110 / 205 / 220 1) | 110 / 120 / 230 | |

|

Voltage tolerance (nominal voltage) |

% |

± 10 | ||

|

Power consumption |

W |

30 | ||

|

Duty cycle |

% |

100 | ||

|

Switching time according to ISO 6403 |

ON |

ms |

20 … 50 | |

|

OFF (without rectifier) |

ms |

5 … 25 | ||

|

OFF (with rectifier) |

ms |

30 … 50 | ||

|

Maximum switching frequency |

1/h |

15000 | ||

|

Protection class according to DIN EN 60529 |

IP65 (with mating connector mounted and locked) | |||

|

Maximum coil temperature |

°C |

150 | ||

| 1) | Other voltages upon request |

In the electrical connection, the protective earthing conductor (PE, grounded) is to be connected in accordance with the stipulations.

The electric connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

|

Connection voltage (DC voltage) |

V |

24 | ||

|

Voltage tolerance (connection voltage) |

+30 %/-15 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

400 | ||

|

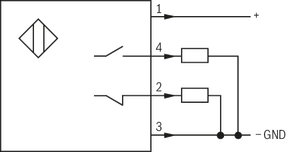

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

400 | |

|

3 |

Earthing (GND) |

V |

0 | |

|

M12x1 plug-in connections 1) |

K72L | ||

|

Available voltages 2) |

V |

24 | |

|

Limited switch-off voltage peak |

V |

-44 … -55 | |

|

Voltage tolerance (nominal voltage) |

% |

± 10 | |

|

Power consumption |

W |

30 | |

|

Duty cycle |

% |

100 | |

|

Switching time according to ISO 6403 |

ON |

ms |

30 … 50 |

|

OFF (without rectifier) |

ms |

10 … 20 | |

|

OFF (with rectifier) |

ms |

35 … 45 | |

|

Maximum switching frequency |

Standard |

1/h |

15000 |

|

Protection class according to DIN EN 60529 3) |

IP65 | ||

|

Protection class according to DIN EN 61140 |

III | ||

|

Maximum coil temperature 4) |

°C |

150 | |

| 1) | Mating connectors according to IEC 60947-5-2, separate order, see data sheet 08006 |

| 2) | Connection to functional low voltage with secure separation only = PELV/SELV |

| 3) | Only with the use of the mating connectors indicated by us and with correct installation. |

| 4) | Due to the surface temperatures of the solenoid coils, the standards ISO 13732-1 and EN 982 need to be adhered to! |

|

Size |

10 | ||

|

Maximum operating pressure |

Port P |

bar |

350 |

|

Port A |

bar |

350 | |

|

Port B |

bar |

350 | |

|

Maximum flow |

l/min |

40 | |

|

Hydraulic fluid |

see table | ||

|

Hydraulic fluid temperature range |

NBR seals |

°C |

-30 … +80 |

|

FKM seals |

°C |

-20 … +80 | |

|

Viscosity range |

mm²/s |

2.8 … 500 | |

|

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) |

Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

For applications outside these parameters, please consult us!